Ever since I was a kid I’ve been fascinated with building / creating things. In middle school I remember finding some blueprints online for a hovercraft from plywood and a leaf blower. After making it and watching it work, I was obsessed. In highschool I took a woodshop class that was equally awesome. I remember trying to convince my parents and everyone I knew that it would be a good investment to buy a laser engraver. Then laser cutters. I still think its a good idea – you can make so much stuff with it!

Then came 3d printers, and the technology has been out for a while. I’ve been busy focusing on my startup and didn’t really have any time to think about 3d printing. Slowly I began to champion the technology more and more, telling everyone about my visions for the future and almost every one involves some sort of 3d printing technology.

As soon as I realized that I made it a mission to buy a 3d printer – and that’s how the research began.

There are a ton of 3d printers on the market, with new ones coming out every week and plans for new versions constantly in the pipeline. This makings finding the perfect printer a tough process.

Variables to Consider:

Speed – Some 3d printers build at a slow 20 mm/s while others can print at 100 mm/s. On larger builds this can save hours.

Quality – The precision of the machine is extremely important. Some printers look like something made as a hobby while others look like injection molding and the precision is such that you can barely even see the extrusion lines.

Price – 3d printers can vary in price greatly – you can get a kit for $300, or a fully assembled machine for $2,000+. On the very high-end there are $25,000+ 3d printers, like the ones Shapeways uses.

Noise – Some printers can get pretty loud when the fan is running, while others sound like a normal printer.

Ease of Use – How much tinkering its going to take it to work consistently. Some machines are really fragile.

Types of Materials – Some printers only work with PLA filament, while others work with both PLA and ABS filament.

Product Quality – Some printers are made out of plywood and printed parts, while others are made out of high quality machined metal.

Kit vs Assembled – Some 3d printers come only as a kit, some come as an assembled machine

Open source vs Proprietary – Some printers are built on open source hardware (like RepRap) and others are closed. Similar deal with software, some run on open source software while others like makerbot have closed, proprietary software.

Features – There are a bunch of features that are specific to certain machines, while other features are more widespread. Things like heated beds are almost ubiquitous, while dual extruding is something less printers are capable of.

Support – Naturally there is going to be a lot of tinkering, so having a quick way to contact the makers incase a problem occurs is critical.

Upgrades – It would be ideal to purchase a printer where the manufacturer builds later versions so that older versions can upgrade and they don’t have to purchase entirely new machines every time they want to upgrade to the newest tech.

My Preferences:

Speed – Speed is very important to me. This threw out a lot of the slower printers like the Cube3d. Ideally looking for something that prints consistently at 100 mm/s but has the capacity to push 150 mm/s

Quality – To me this was the most important factor. Good printers can hit 100 microns, while really good printers can eve get down to 50 microns printing at full speed.

Price – Was willing to spend $2,500 on a printer, so I could pretty much choose any desktop printer on the market. While the overall price was not much of a factor – price per performance was an extremely important factor. If I could buy a great printer for $700 and only get minimal performance upgrades from spending $1500 on a slightly higher quality printer than I’m better off with the cheaper one.

Noise – Not really a factor for me.

Ease of Use – I’m pretty tech savvy and half the fun for me will probably be the tinkering. That said, I wanted my first machine to be rock solid, because I plan on using it to print the materials to create a 2nd machine, which will be my “tinker” machine.

Types of Materials – I wanted a printer that was able to print with both PLA and ABS filament.

Product Quality – Looking for high quality – so the ones made out of wood are likely not for me. I wanted something sturdy and well built for my first printer.

Kit vs Assembled – For my first printer I’m looking for something I can plug in and start printing, so I’m going to want a fully assembled machine. I’ll save the kit for my second machine once I’m familiar with how everything works.

Open Source vs Proprietary – Definitely looking for open source software. I’ll probably use open source hardware plans (RepRap) for my second machine.

Features – Definitely need a heated print bed to stop warping on ABS prints. Need a large build platform. Dual extrusion would be cool but not critical.

Support – Very important that the guys making the printer are easily accesable. This is two fold – one if I have a question and two if I come up with an idea involving 3d printing it would be great to already have a relationship built with someone who knows the in’s and outs.

Upgrades – Since I’m in this for the long haul and don’t want to keep buying printers as the technology quickly advances, I very much need to buy from a company that will support backwards compatibility with their upgrades and use common parts so the older generations can upgrade to the newer ones without buying a brand new machine.

Other: Didn’t want to buy one from KickStarter (too experimental – would rather wait until they’re a real company).

Price Comparison for Most 3d Printers:

http://www.3ders.org/pricecompare/3dprinters/

I’ve pretty much read all of the youtube, google groups, reddit discussions revolving around the pros and cons of each printer. Eventually I was able to narrow it down to a short list of candidates:

MakerGear M2 – $1,700

Likely the best printer on the market when considering price, speed, quality. Available both in a kit and fully assembled. Prints consistantly at 100 mm/s , minimal tinkering, high quality design & construction, heated glass print bed. Probably the quickest printer to go from the shipping box to creating 3d prints – just plug it in and with minimal tinkering you should be good to go. Great support via the IRC channel (thanks Rick!)

Afina H-Series – $1,500

The Afina is well recommended everywhere. Great print quality, quite, fast, reliable etc. The problem for me is it has a really small print bed. This may have been my second place if it was a bigger machine.

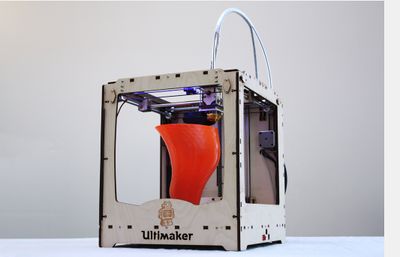

Ultimaker – $1,600

As far as complete printers go, the Ultimaker may be up there with the Afina and MakerGear M2. Definitely a good printer, just didn’t like the wood construction. Quality and speed wise it probably rivals the M2 or Afina. Also comes as a kit or fully assembled which is good if you want to choose. Pretty big print area which to me makes it a better overall printer than the Afina. Looks exactly like the Type A and all the other wood designs, which really don’t like.

Type A Machines Series 1 – $1,400

The Type A Machine was recommended on a lot of forums and was a top contender. It has a heated glass bed, good speed and produces high quality prints. The problem for me was that its made out of plywood and looks a lot like the Ultimaker. This isn’t to say its not a great printer, but if I’m spending $1,400 I want it to look bad-ass.

LulzBot A101 – $1,725

Another great choice – its built off the mandel RepRap blueprints, with a higher quality build. It has some 3d printed parts I think. Heated glass print bed which is good too. Didn’t find any real cons for this machine other than when it comes to speed and quality there are other better machines for the price.

MakerBot Replicator 2 – $2,799

The Replicator is probably the most well known 3d printer which is made by – they sort of started the movement and had some great traction behind their initial PR campaign. After further investigation there are a few things turned me away from the Replicator 2. The first is closed source software, which kinda sucks. The second is I’ve heard a lot of people have problems with the replicator as far as needing to tinker with it a lot to get a good print. I think the X2 has dual extruders, which is awesome. They also own Thingiverse which is cool, but not cool enough to make me buy this printer.

Solidoodle 3 – $799

The Solidoodle 3 is one of the best low price printers. If you’re trying to squeeze every ounce of quality, speed, then you’re better off going with a more expensive printer, but if price is a large factor then the Solidoodle may be your best friend. Its sturdy, has a large heated print bed, pretty good quality and pretty good speed. It’s also the 3rd generation for this company so they know what they’re doing and they have a great forum for support.

PrintrBot Jr – $499

Printrbots are actually pretty cool – they come in a bunch of different sizes, and even though they’re made out of wood it’s kinda fine because you’re not paying that much for it. Overally they have good print quality, and are pretty quick, but the individual components are just not as high quality as the more expensive printers.

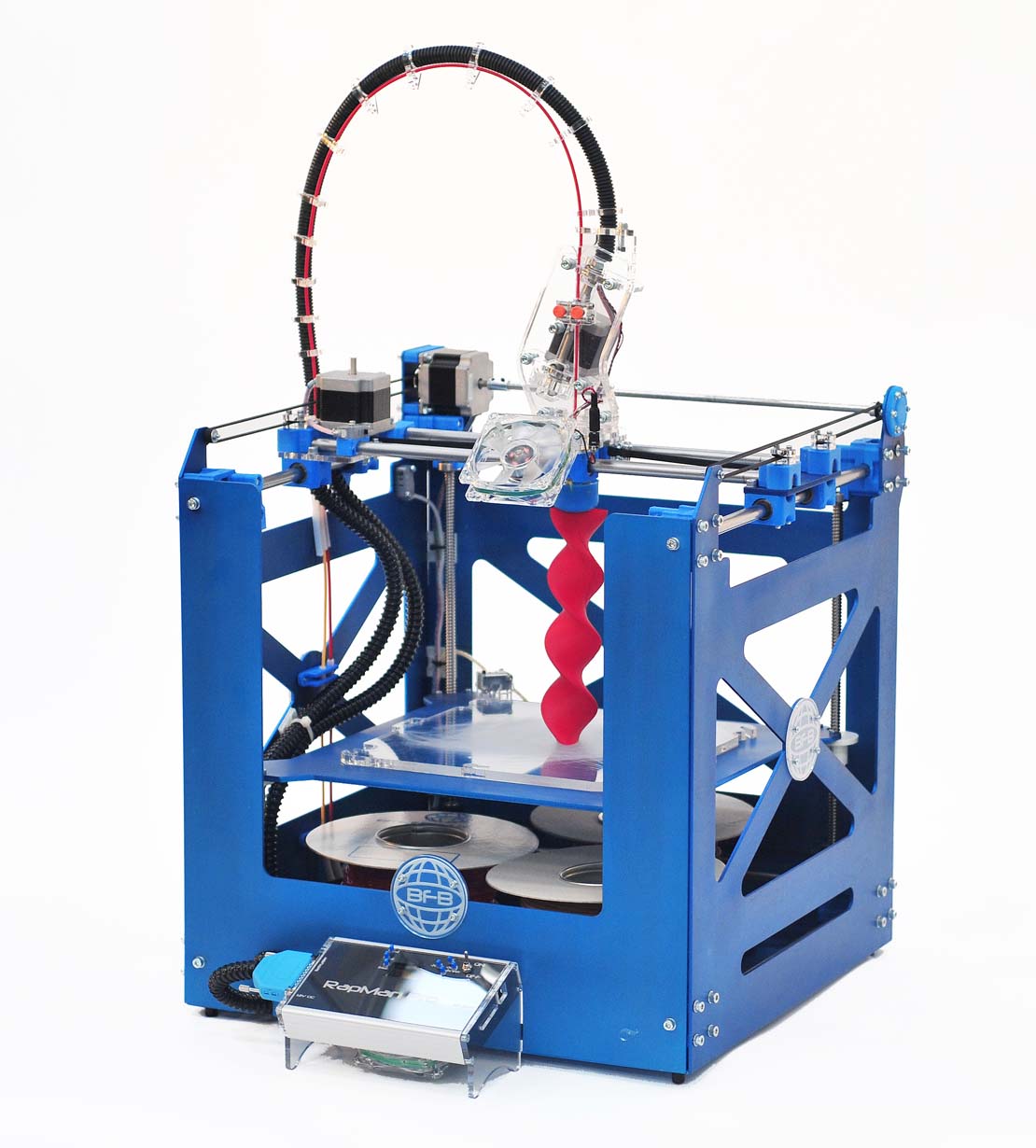

Prusa Mandel RepRap – $300-700

This is probably the printer I’ll be making – fully open sourced designs means you can basically just go find the parts and build it yourself from scratch. No markup, it costs whatever you can find the parts for (which is actually getting pretty cheap – could get down to $200 if you really wanted to). This design is used on a number of printers like the Lulzbot and BukoBot.

My Winner – MakerGear M2:

For me it had the perfect combination of features, speed, quality, and price. It is probably the highest quality printer on the market, it works right out of the box and takes minimal calibration to get it working with fine precision. I jumped on the IRC to ask a few questions and Rick the founder of MakerGear answered my questions in 5 minutes which was awesome. Good to know I have a resource I can use if I ever have any problems I can’t figure out how to fix.

For me it had the perfect combination of features, speed, quality, and price. It is probably the highest quality printer on the market, it works right out of the box and takes minimal calibration to get it working with fine precision. I jumped on the IRC to ask a few questions and Rick the founder of MakerGear answered my questions in 5 minutes which was awesome. Good to know I have a resource I can use if I ever have any problems I can’t figure out how to fix.

More Reviews:

To go review hunting on your own, here are a few good places to start:

http://www.reddit.com/r/3dprinting

https://groups.google.com/forum/?fromgroups#!forum/makerbot

https://groups.google.com/forum/?fromgroups#!forum/makergear

Software & Websites:

http://thingiverse.com/ – Place to download tons of 3d files you can print out directly on your printer.

http://doodle3d.com/ – Awesome Kickstarter that allows you to basically draw things in 2d and then print out your drawings on your 3d printer.

https://tinkercad.com/ – Good CAD software for making basic 3d models.

http://www.openscad.org/ – A bit more professional 3d modeling software

http://meshlab.sourceforge.net/ – to view 3D models and convert between model file formats

http://www.netfabb.com/ – repair STL files for printing – sometimes models have holes or need other fixes before being sliced

http://slic3r.org/ – Helps slice 3d models by turning STL files into instructions for the printer to execute in gcode. There are a lot of print and printer settings that need to be set in Slic3r and these will determine the quality of your print. Print settings include infill density and pattern, speed, layer height and others.

https://github.com/kliment/Printrun – Software to interact with the printer so you can start and pause prints, trigger the motors, turn off fans, set temperatures and send other signals to operate your printer.

More Materials:

There are several materials that could be used for 3d printing in the near future. I think printing in glass (from sand) is one of the more interesting – glass is a very useful material and it shouldn’t be hard to heat up the sand. Some people are already experimenting with this. There are already 3d printers that work with metal, but they are extremely expensive. Since the tech exists, it should only be a few years until someone figures out how to make the process cheaper. Carbon Nanotubes should also be very interesting but I think that may be a little bit further out. Some easy materials would be flexible plastic, rubber, and something wearable (like synthetic cotton).

Programmable Products: I believe that if we can create a smart material that will interface with a Makey-Makey and allow for programmer, we will be able to do some really interseting things. Adding things like acceloromoters and other to a material that can be heated and printed without breaking would be a monumental breakthrough.

Medicine: There are many advances in medicine that we can attribute to 3d printing. Using stem cells we have successfully printed a Ear – and are also working on printing working kidneys and hearts. In addition, using special biocompatible plastics we are printing custom body implants like bronchial shunts. We also use 3d printing technology to make custom prosthetics for amuptees a lot quicker, faster, and cheaper.

Clothing & Fashion: By experimenting with different design patters we are able to create interesting textures that work as clothing. As we gain the ability to print with more materials, the future of fashion may be a host of clothing design files where users can print the clothing right on their desk if the have the right materials. Designers would be incentivized to make their designs work with the most common materials so there are more people who are able to purchase & print.

Food & Nutrition: It should be possible to create a 3d printer that uses a powders like Soylent for Nutrients, Flavors, Colors and Textures, and mixes them together with water or oil to create a sufficient printing material. This would allow people to store foods in powder form for long periods of time without spoiling. All they would need is a printer and their cartridge that has enough nutrients to give them a few weeks of printed food.

devis pour fenetre pvc

Jun 3, 2013 -

Greetings! This is my first comment here so I

just wanted to give a quick shout out and say I really enjoy reading through your

articles. Can you recommend any other blogs/websites/forums that deal

with the same topics? Thanks for your time!

Andrew

Jun 3, 2013 -

Lol.. dual extruders, I got 3, with capacity for 4.

Adam Setapen

Jun 4, 2013 -

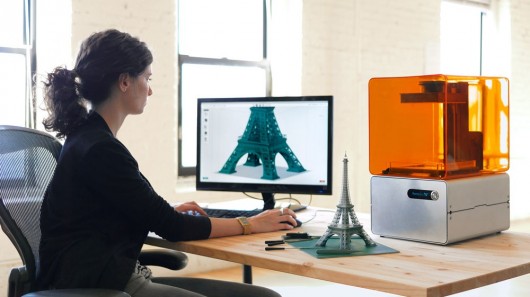

Using the Formlabs printer as the header without mentioning it? Psssh.

juliansarokin

Jun 6, 2013 -

oops! Going to go through and update the post with some more coverage on SLA printers like Formalabs and some SLS printers as well. Formlabs had the best picture to illustrate 3d printing in one HQ shot!

James

Jun 7, 2013 -

A nice 3D printer price comparison: http://www.3dprintfox.com/ultimate-3d-printer-price-comparison.php

meble klasyczne

Jun 19, 2013 -

fantastic put up, very informative. I ponder why the opposite specialists of this

sector don’t understand this. You should proceed your writing. I am sure, you’ve

a great readers’ base already!

fuck me

Jul 16, 2013 -

Fantastic blog you have here but I was curious if you knew of any discussion boards that

cover the same topics discussed here? I’d really love to be a part of community where I can get feedback from other experienced people that share the same interest. If you have any suggestions, please let me know. Thanks!

bonus zeturf

Aug 3, 2013 -

Can I simply just say what a relief to uncover somebody who really knows what they’re talking about on the internet. You certainly understand how to bring a problem to light and make it important. More people should read this and understand this side of the story. I was surprised that you aren’t

more popular given that you most certainly have the gift.

Brody S

Aug 18, 2013 -

Hello. I am currently trying to research and figure out how to go about making a home made vinyl toy. I have seen alot of articles on the subject and even some posted questions on this website about it as well but no one seemed to have the information I needed. I’m hoping someone will see this question and be able to offer me the information or advice I’m looking for.

Here goes…

I’m trying to make a custom toy at home.

I would like it to be vinyl or atleast vinyl like. Sort of like the toys you usually see such as baby dolls, old troll dolls, dunnys, etc…

I do not however want to have to send off my idea to a company to make it for me as most people suggest doing.

I also do not want to go about either buying or making a vacuum mold.

I want to make it completely from home some how.

I just need to know the best and easiest way of doing such.

I just need to get some ideas of alternatives to sending it off, vacuum molding alternatives,etc…

Also if there is anyone who knows of a material that is easier to use and would give a very similar look and feel like vinyl I would love to know what it is. Something moldable or pourable is fine.

Thank you for any help you can give me!!!!

3d Printer Kit Comparison Essays Topic | 3D Printers

Feb 22, 2015 -

[…] Thinking of Buying a 3D Printer? Here’s What You Need … – oops! Going to go through and update the post with some more coverage on SLA printers like Formalabs and some SLS printers as well. Formlabs had the best picture to …… […]